4. STRATEGY, PRINCIPLES AND LOCATIONS FOR MINERALS RELATED DEVELOPMENT

Provision to be met

An annual aggregates provision rate for Northamptonshire is required to be made in this plan to ensure an adequate and steady supply of aggregates is maintained to meet anticipated needs of the construction industry and growth.

The NPPF sets the requirement for MPAs to prepare LAA’s which provide the basis for identifying the plans aggregate provision rates. This method of calculation replaces the previous sub-regional approach to apportionment determination where a nationally prescribed regional apportionment figure was sub-divided within each region.

Northamptonshire’s aggregate provision rate is for an average annual figure of 0.89 Mt of aggregates to be provided consisting of 0.50 Mt of sand and gravel and 0.39 Mt of crushed rock (limestone) per annum.

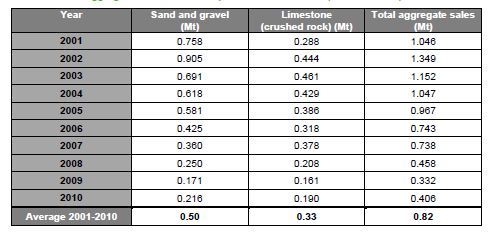

The figure for sand and gravel calculated on the basis of average aggregate sales over a ten year rolling period (2001 – 2010) is 0.50 Mt per annum (Mtpa). The figure for crushed rock calculated on the basis of average aggregate sales over a ten year rolling period (2001 – 2010) was 0.33 Mtpa. This was increased to 0.39 Mtpa to reflect the steady increase in sales in recent years and the increase in sites that have been coming forward for permission and being implemented, unlike for sand and gravel. Table 2 below shows the average aggregate sales over a ten year rolling period (2001 – 2010).

Table 2: Total aggregate sales in Northamptonshire 2001 – 2010 (million tonnes)

Movements of aggregates into and out of Northamptonshire are not self-balancing. Northamptonshire is a net importer of both sand and gravel and crushed rock; imports outweighed exports by 23% and 250% (of the county’s total production) respectively. The destination of the majority of Northamptonshire’s sand and gravel is largely unknown other than being within the East Midlands. The main destinations for sand and gravel exported beyond the region include the adjoining county of Bedfordshire in the East of England, and the West Midlands region. Sand and gravel is imported from within the East Midlands. The origin of imports from beyond the region is largely unknown. The majority of Northamptonshire’s crushed rock is exported to the adjoining area of Cambridgeshire and Peterborough and elsewhere within the East of England, with the remainder exported to the East Midlands and South East. Crushed rock is imported only from the East Midlands region, with the majority supplied from Leicestershire and Rutland.

Northamptonshire cannot be expected to provide the resources for growth solely from within the county. This is because, like most authorities, not all of the different types of material required to support growth are found within the county, but also because greater imports are expected into Northamptonshire as it is usual for aggregate movements to be into areas of higher growth to support development. The permission at Wakerley is likely to assist in addressing any imbalance regarding crushed rock. Notwithstanding this more allocations are identified in the plan than is required to meet the plans total provision.

Within Northamptonshire the provision of aggregates effectively refers to sand and gravel and crushed rock (limestone) for which sufficient allocations have been identified in the Local Plan to meet the required provision.

To meet the needs of growth in Northamptonshire it may be more sustainable for certain aggregate requirements related to major construction works to be met from borrow pits; therefore a specific policy addressing borrow pits has been included in the Local Plan (Policy 9).

A specific provision figure for building and roofing stone is not identified in the Local Plan, but the promotion of building and roofing stone extraction is contained in a specific policy identifying the criteria against which proposals would be judged. In addition specific sites for building or roofing stone extraction are also included in the Local Plan.

There will not be provision made for the extraction of refractory minerals, this will be met through incidental working of other sites for extraction. Working of limestone for agricultural purposes other than that permitted under the provisions of the Town and Country Planning General Permitted Development Order 1995 will not be provided for.

Policy 1 – Providing for an adequate supply of aggregates

Provision will be made over the plan period 2011 to 2031 for the extraction of:

- 10 million tonnes of sand and gravel (equivalent to an annual average of 0.50 million tonnes) provided from glacial and pre-glacial deposits, and the river valleys of the Nene (west of Wellingborough) and the Great Ouse.

- 7.8 million tonnes of crushed rock (limestone) (equivalent to an annual average of 0.39 million tonnes) provided from deposits outside unworked river valleys or from sites with old permissions upgraded to modern conditions.

The maintenance of a landbank of at least seven years for sand and gravel, and at least ten years for crushed rock will be sought.

This provision will come from both extensions to existing sites and new sites if they meet the spatial strategy for mineral extraction and are assessed as meeting environmental, amenity and other requirements of the Local Plan. Allocations to meet the required provision are identified in the Local Plan.

Landbanks

A landbank is a stock of planning permissions for mineral extraction over a specified time period. Government guidance requires landbanks to be maintained for all aggregate minerals, with the recommended landbank period for sand and gravel being at least seven years. A longer time period of at least ten years is recommended for crushed rock. However, landbanks can only be maintained in practice if the minerals industry comes forward with planning applications in the right place at the right time. In Northamptonshire there has been a long period where the landbank for sand and gravel has been below these figures, but where this has not impacted on the annual provision being delivered. Nevertheless, the aim will be to maintain and at the end of the plan period, have a landbank of at least seven years for sand and gravel and at least ten years for crushed rock based on the annual provision rates. To this end the plan will seek to identify sufficient allocations to provide for the maintenance of landbanks at the end of the plan period. This equates to an additional 3.5 Mt of sand and gravel and 3.9 Mt for crushed rock (limestone).

Old minerals permissions for crushed rock (limestone) extraction

The supply of crushed rock as aggregate in Northamptonshire has traditionally been met through a combination of old minerals permissions and permissions granted specifically for limestone. However, sites with old permissions are effectively dormant and do not give a true reflection of what the approved supply, and therefore the landbank, is in reality. Unless identified as an allocated site in the Local Plan, old minerals planning permissions (including those with modern planning conditions) will not be taken to contribute towards the provision of aggregates and the maintenance of a landbank. It is not expected that sites with old permissions that are not identified in the Local Plan will come forward, but if they do such permissions will be treated as a windfall increase to Northamptonshire’s aggregate provision rates.

Commitments

This Local Plan does not specifically include commitments (i.e. sites with planning permission or equivalent) for minerals-related development. However, these commitments make a fundamental contribution in providing adequate supply of aggregates throughout the plan period, and for the Local Plan to meet its objectives.

Sand and gravel

At the commencement of the plan period, there were six sand and gravel sites that had planning permission:

- Bozeat, Church Farm,

- Earls Barton Spinney,

- Earls Barton West,

- Passenham,

- Thrapston, Castle Manor Farm, and

- Warmington, Elton Estate (agricultural reservoir).

Since the commencement of the plan period (and up to 1 January 2016), planning permission has been granted at Lilford Lodge Farm, White Mills Marina and Passenham Quarry South Extension. All sites are operational apart from Earls Barton Spinney and Earls Barton West (where extraction commenced to implement the permissions only but remain inactive) and Castle Manor Farm, Thrapston (now fully worked). The sand and gravel quarry at Passenham is active but is currently only processing materials from across the county border in Milton Keynes (and this does not count towards Northamptonshire provision). During the period 1 January 2011 – 31 December 2015 sales comprised 1.93 Mt.

The baseline position for the Local Plan is that the estimated committed reserves for Northamptonshire were 3.94 Mt as at 1 January 2016.

Crushed rock

At the commencement of the plan period the following crushed rock sites with planning permission were operational:

- Collyweston, Duddington (limestone),

- Harlestone (sandstone),

- Pury End (limestone and building stone), and

- Rushton (limestone).

A further six sites have old mineral planning permissions which were reviewed under the Environment Act 1995 with modern conditions agreed. All sites were inactive (with the exception of Priors Hall):

- Cowthick Quarry / Weldon Landfill (ironstone and overlying minerals),

- Park Lodge (ironstone and overlying minerals),

- Pitsford (ironstone and overlying minerals),

- Priors Hall (ironstone and overlying minerals),

- Wakerley (ironstone and overlying minerals), and

- Weekley / Geddington (ironstone and overlying minerals).

The commitment with modern conditions at Wakerley is to be discounted from this Local Plan and instead substituted with the Wakerley site as permitted. The Wakerley site has been effectively re-shaped (from that of the old mineral planning permission) to reduce potentially adverse environmental effects. Planning permission for the Wakerley site was issued in December 2015 following signing of the S106 agreement. The site has a ten year implementation period from issue of planning permission. The estimated yield from this site is 11.25 Mt, with 6 Mt expected to be extracted up to 2041.

The quantity of the economically viable resources at the above locations, other than Wakerley, was not known at the commencement of the plan period. The Priors Hall site has been worked in connection with an adjacent urban extension with extraction ceasing in 2014.

In addition there were a further 28 dormant ironstone sites in Northamptonshire. No prohibition or revocation orders have been served to date on these sites with the exception of Land at Boughton-Pitsford-Moulton (dormant but subject to ROMP in 2014 due to the intent to extract the small amout of remaining crushed rock and building stone reserves). The MPA has no intention to serve any other prohibition or revocation orders for the foreseeable future. The quantity of economically viable mineral resources, if any, within these dormant sites is unknown.

Since the commencement of the plan period (and up to 1 January 2016), planning permission has been granted at: Harley Way, Oundle (operational) with a primary focus on the extraction of building stone; Ringstead Grange (operational); and Stonehill Quarry, Wansford (operational). During the period 1 January 2011 – 31 December 2015 aggregate sales comprised 1.1 Mt.

The baseline position for the Local Plan is that the estimated committed reserves4 (excluding the dormant sites) for Northamptonshire were 9.86 Mt as at 1 January 2016.

4Only 6 Mt from the Wakerley site has been included in calculations as although the estimated yield from this site is 11.25 Mt, it is thought that only 6 Mt of this will be extracted up to 2041.

To meet the provision of 0.39 Mtpa up to 2031 as set out in the Local Plan (Policy 1) and maintain a landbank of ten years beyond the plan period (i.e. up to 2041) a total of 11.7 Mt is required; minus the estimated committed reserves (9.86 Mt) and aggregate sales (1.1 Mt), leaving a figure of 0.74 Mt of crushed rock (limestone) for which allocations need to be identified.

Building and roofing stone

At the commencement of the plan period the following sites had planning permissions that, as well as providing for crushed rock, included extraction of building and roofing stone:

- Duddington (roofing stone),

- Harlestone (building stone),

- Pury End (building stone),

- Rushton, Storefield Lodge (building stone), and

- Pitsford (building stone).

Of the above, all sites except Pitsford were operational.

Since the start of the plan period (and up to 1 January 2016) planning permission has also been approved at: Harley Way, Oundle (operational); Stonehill Quarry, Wansford (operational); Stonepits Quarry, Benefield (not yet implemented); and Collyweston Slate Mine, Collyweston (not yet implemented). All of which have a primary focus on the extraction of building and roofing stone.

Secondary and recycled materials

Secondary and recycled aggregates represent a potential major source of materials for construction, helping to conserve primary materials and reducing the waste produced.

The NPPF requires aggregate provision to include ‘alternative materials’ (i.e. secondary and recycled materials). A specific provision rate is not identified in the Local Plan, nevertheless, given the importance of such materials, sites for the provision of secondary and recycled materials are required.

At the commencement of the plan period (and up to 1 January 2016) the following sites had planning permission for the processing of recycled materials:

- Astwick Quarry Croughton (now closed),

- Boughton Quarry Northampton,

- Castle Manor Farm quarry Titchmarsh (now closed),

- Collyweston,

- Cowthick Landfill Weldon (inactive),

- (former) Potato Store Oundle Road Corby,

- Gretton Brook Road Corby,

- Harlestone Quarry,

- Kislingbury Composting Site Wrights Lane, Kislingbury (inactive),

- Lakeside Works Crow Lane Great Billing,

- Land at Passenham Quarry (inactive),

- Land north of A45, between M1 Junction 16 and Upper Heyford,

- Long Drow Pits Weekly Wood Geddington,

- Monkton Sidings Fineshade,

- Nielson Road Finedon Road industrial estate Wellingborough,

- Northampton Coating Plant Great Billing,

- Ringstead Grange Quarry,

- Rushton Landfill Site,

- The Old Brickworks Harborough Road Pitsford,

- The Old Sewage Works, Blisworth,

- Tweed Road, Northampton, and

- Weldon Landfill Site, Corby (inactive).

Other sites associated with significant development works (e.g. onsite waste management for key construction / demolition works) have also been operational during this period but, due to their temporary (short-term) nature, have not been identified.

Refractory minerals / clay

Northamptonshire has two sites with permission to extract refractory minerals and / or clay: East Northamptonshire Resource Management Facility (ENRMF) and Nassington. The former is part of the ENRMF landfill site. The latter is related to a foundry that has now closed and under the current permission no material can be exported off site.

Sand and gravel and crushed rock

Spatial strategy for mineral extraction

Although minerals can only be extracted where they are found, the mineral resources within Northamptonshire are significant and it is appropriate in the context of long term minerals planning to establish a clear spatial strategy for their extraction.

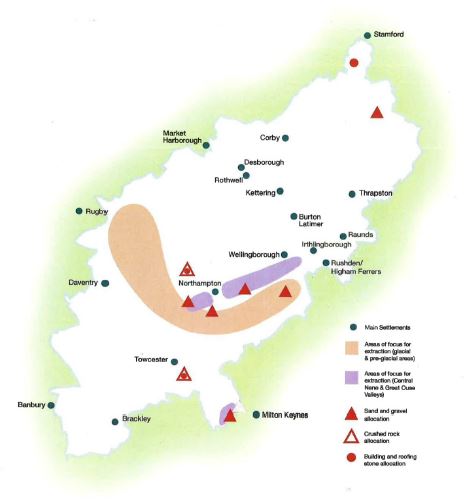

The spatial development strategy for mineral extraction in the county is to focus extraction in glacial and pre-glacial areas, and selected river valleys where there is currently or has been mineral extraction. River valley provision will therefore come from the Nene Valley west of Wellingborough and the Great Ouse Valley. This strategy acknowledges that supply and quality issues are the key to delivering aggregates for growth. In river valleys, restoration should not be predominantly to lakes or large areas of open water.

Inclusion of parts of the Nene and Great Ouse Valleys supports the strategic approach of having locations for minerals and waste development that are closely related to existing and proposed development; with the Nene locations directly supporting growth at Northampton and Wellingborough, and Great Ouse locations linking to Towcester.

Allocations for sand and gravel sites comply with the spatial strategy and include both extensions to existing sites and new sites. There will be no requirement to identify sites for soft sand provision, to meet a notional provision of soft sand from within the wider sand and gravel provision rate, due to this not being a national requirement. However soft sand sites can be identified if assessments identify such sites as appropriate for allocation.

The spatial strategy focuses on sand and gravel extraction as this is where a clear spatial approach to identifying provision is required. Should proposals come forward for working old mineral permissions, a reduction in the impact of sites and, where appropriate, of their size will be sought through the process of negotiating modern conditions.

Plan 3: The spatial strategy for mineral extraction

Note: The spatial strategy for mineral extraction is illustrated in Plan 3. It is important to note that Plan 3 is a diagrammatic representation only and should not be used to identify specific sites. Where more accurate detail is required regarding actual delineation (i.e. ground-truthing) reference should be made to the British Geological Survey (BGS) Digital Geological Map of Great Britain and Ordnance Survey MasterMap. However it is widely recognised that the BGS mapping is not comprehensive and as such in areas included within the spatial strategy that are not identified on BGS mapping site specific evidence may be required to demonstrate a proven resource.

Policy 2 – Spatial strategy for mineral extraction

The spatial strategy for minerals extraction within Northamptonshire is to focus extraction on the county’s pre-glacial and glacial deposits together with the reserves from the river valleys of the Nene (west of Wellingborough) and the Great Ouse.

Development principles for mineral extraction

The Local Plan identifies sufficient sites for both sand and gravel and crushed rock to meet the plans total provision and for the maintainence of landbanks at the end of the plan period. As such preference will be given to proposals for development on allocated sites. Proposals for sand and gravel and crushed rock extraction at unallocated sites (including extensions to existing sites and extensions to allocated sites), will be required to robustly justify the requirement for extraction, specifically in relation to the need for the site to maintain supply in line with the adopted Local Plan provision rates and / or the maintenance of the aggregates landbank.

Determination of proposals for the extraction of sand and gravel and crushed rock will be made in line with Policy 3. Proposals should also seek to comply with the spatial strategy for mineral extraction set out in the Local Plan (Policy 1).

Policy 3 – Development criteria for mineral extraction

Proposals for the extraction of minerals from non-allocated sites (including extensions to existing sites and extensions to allocated sites) must demonstrate that the development:

- does not conflict with the spatial strategy for mineral extraction,

- where relating to aggregates, that it is required to maintain an adequate supply of minerals in accordance with the adopted Local Plan provision rates and / or the maintenance of a landbank,

- is required to meet a proven need for materials with particular specifications that cannot reasonably or would not otherwise be met from committed or allocated reserves,

- will maximise the recovery of the particular reserve whilst minimising waste through operational techniques employed, and

- promotes the most appropriate end-use of materials, and specifically ensure that building and roofing stone is used for high quality end-uses and not aggregate.

In addition to the above, proposals for the extraction of building and roofing stone must specifically demonstrate that: it supports the supply of locally sourced building materials (including varieties of limestone, ironstone, sandstone and Collyweston slate); and the principal purpose of the extraction is for building and roofing stone (as such the proportion of stone and aggregate production should be identified).

Allocations for mineral extraction

It is important to note that the allocation of sites within this Local Plan does not equate to the grant of planning permission. Any proposal for development of an allocation will still need to meet the requirements set out in the Local Plan.

Sand and gravel

The sites allocated for sand and gravel (under Policy 4) have a total estimated provision of 7.75 Mt. This, in addition to the estimated committed reserves of 3.94 Mt (at 1 January 2016) and sales of 1.93 Mt (for the period 2011 – 2016), equates to a total of 13.62 Mt, and will meet the required provision of 13.5 Mt for the plan period plus maintenance of landbanks at the end of the plan period (with an overprovision of 0.12 Mt). The allocated sites and their likelihood of delivery will be monitored throughout the plan period. In order to maintain flexibility and ensure that the plan can respond to market drivers, the plan allows for unallocated sites to come forward if in line with Local Plan policies.

The currently worked river valleys of the Nene between Northampton and Wellingborough and of the Great Ouse, will play a significant role in delivering the provision to be met. The Earls Barton West extension site (M4) will provide the vast majority of the worked river valley supply. This site will help to ensure continuity of good quality supplies throughout the plan period and thus complement and support the pre-glacial and glacial allocations. The Milton Malsor site (M1) will provide soft sand; all other sites will provide sharp sand and gravel.

The Elton Extension site, although not located within the areas of focus identified in Policy 2, is an extension to an existing operation (Elton Estate, Warmington) and will help to maintain a balance of supply across the county.

As the former gravel pits in the Nene Valley are now designated as a site of European importance in relation to birds (Upper Nene Valley Gravel Pits SPA), it is important that further extraction from allocated sites in this valley will not lead to adverse effects on the integrity of this designation. Potential sites were subject to HRA through the plan-making process. The planning application for mineral extraction at the Earls Barton West extension (M4) site will be required to undergo further HRA to ensure that development would not adversely affect the integrity of the SPA sites.

Policy 4 – Sites for the provision of sand and gravel

A supply of sand and gravel to contribute to meeting the provision of sand and gravel will be provided for by: production since 1 January 2011, sites with planning permission as at 1 January 2016 and the following allocated sites.

Pre-glacial and glacial areas

M1: Milton Malsor 1.2 million tonnes (approximately)

M2: Strixton - Bozeat 1.5 million tonnes (approximately)

Central Nene Valley

MA3: Heyford 1.4 million tonnes (approximately)

MA4: Earls Barton West Extension 2.6 million tonnes (approximately)

Great Ouse Valley

M5: Passenham Extension South 0.2 million tonnes (approximately)

Other locations

M6: Elton Extension 0.85 million tonnes (approximately)

Crushed rock (limestone)

Both the Harlestone and Pury End Quarry Extensions have been allocated primarily for their contribution to the provision of building stone (under Policy 7) but will also contribute to crushed rock provision (combined estimated provision of 1.66 Mt).

The sites allocated for crushed rock have a total estimated provision of 1.66 Mt. This, in addition to the estimated committed reserves of 9.86 Mt (at 1 January 2016) and sales of 1.1 Mt (for the period 2011 – 2015), equates to a total of 12.62 Mt, and will meet the required provision of 11.7 Mt for the plan period plus maintenance of landbanks at the end of the plan period (with an overprovision of 0.92 Mt).

Policy 5 – Sites for the provision of crushed rock

A supply of crushed rock to contribute to meeting the provision of crushed rock (limestone) will be provided for by: production since 1 January 2011, sites with planning permission as at 1 January 2016 and by the following allocated sites.

M7: Pury End Quarry Extension (limestone and building stone) 0.85 million tonnes (approximately)

M8: Harlestone Quarry Extension (limestone and building stone) 0.81 million tonnes (approximately)

Building and roofing stone

Building stone produced in Northamptonshire includes ironstone, sandstone and limestone which range in colour and texture. Collyweston stone slate is used locally for roofing. These traditional materials play an important role in the restoration of historic buildings and are also used in new buildings, extensions and walling in order to preserve and enhance local distinctiveness and local building character.

The use of locally sourced building and roofing stone has become a significant factor in the promotion of local identity and in creating a sense of place, and as such the demand for traditional building materials has increased. This is particularly relevant where a match to existing stone and roofs is specified for new development (for example, through the use of design codes).

In order for a source of building or roofing stone to be commercially workable a number of physical characteristics or parameters have to be satisfied including colour, texture, hardness and homogeneity. It is important to recognise that building and roofing stone are quarried from geological formations which may be very restricted in occurrence. In addition, sudden changes in the variability of the deposit can make many areas unsuitable. The working and processing of building and roofing stone generally involves smaller areas and lower production rates than other mineral operations. However, working may continue for very long periods due to the intermittent nature of works.

There is often a large proportion of wastage (overburden) in producing building stone which may be utilised as a construction aggregate. In general, operators receive a higher financial return on building and roofing stone products compared with the aggregate by-product. Due to the variable nature of the deposits, the proportion of aggregate by-product is significantly higher than that of the building and roofing stone won from extraction. Hence the sale of aggregate by-products resulting from the extraction of building and roofing stone assists in off-setting economic costs of extraction. However, Northamptonshire limestone is also not as highly valued as stone sourced from neighbouring counties (in terms of saleable price and demand). Supply of building and roofing stone in the county is therefore limited and in recent years only two sites have consistently worked building stone.

Strategy for building and roofing stone

Unlike for sand and gravel and crushed rock, a specific provision figure for building and roofing stone is not identified. Small scale building and roofing stone extraction is promoted in both rural areas or appropriate locations within settlements, subject to this addressing conservation needs associated with maintaining local distinctiveness in new development, and for the restoration of buildings and structures. This may include the restoration and renewal of existing historic buildings and structures, new buildings in conservation areas and the enhancement of local character and distinctiveness in other sensitive locations.

Policy 6 – Building and roofing stone

Provision of building and roofing stone should be made for its use in:

- the restoration and renewal of existing historic buildings and structures, or

- new buildings in conservation areas, or

- the enhancement of local character and distinctiveness in other sensitive locations.

This provision will come from both extensions to existing sites and new sites subject to being assessed as meeting environmental, amenity and other requirements of the Local Plan. Allocations that will contribute to meeting provision are identified in Policy 7 of the Local Plan.

Development principles for building and roofing stone

It is important that building and roofing stone quarries are operated for the principal purpose of extracting traditional building materials and not just for aggregates under the guise of extraction of stone; this must be clearly demonstrated through proposals for such development. It is understood that although the principal purpose of extraction will be for stone, the sale of aggregate by-products may be required to ensure economic viability and efficient use of resources.

It is possible that additional sites for the extraction of building and roofing stone may be required during the plan period. Determination of proposals for such development will be made in line with Policy 3.

Proposals for the extraction of building and roofing stone on non-allocated sites will be required to show that the stone complements locally sourced building materials and that it will be used for high quality building and / or conservation works, i.e. not for general construction use.

At any time throughout the plan period should the need arise to manage the provision of building and roofing stone to prevent over-supply, or to prevent further provision of general crushed rock aggregates, preference will be given to allocated sites unless there is a proven need on technical grounds (i.e. to provide stone with the technical properties required for restoration works) for a new source of stone to be granted permission.

Allocations for building and roofing stone

Three sites for the extraction of building and roofing stone are allocated in the Local Plan: Collyweston Village; Pury End Quarry Extension; and Harlestone Quarry Extension (the latter two being being extensions to existing operations).

Policy 7 – Sites for the provision of building and roofing stone

Building and roofing stone will be provided for by: sites with planning permission as at 1 January 2016, the following allocated sites, and by any other site that comes forward in line with Local Plan policies.

M7: Pury End Quarry Extension (limestone and building stone) 0.85 million tonnes - limestone and building stone total (approximately)

M8: Harlestone Quarry Extension (limestone and building stone) 0.4 million tonnes – building stone (approximately)

M9: Collyweston Village 50,000 tonnes roofing stone (approximately)

If there is a need to manage the provision of building and roofing stone, allocated sites will be given preference for extraction over non-allocated sites.

Secondary and recycled aggregate facilities

The processing of secondary and recycled aggregates (including inert recycling) represents a potentially major source of materials for construction, helping to conserve primary materials and minimising waste. Sites for the handling, storage and processing of recycled and secondary aggregates (including recycled inert waste) are therefore required to ensure provision of ‘alternative materials’.

Strategy and development principles for secondary and recycled aggregate facilities

No specific provision is made for the processing of secondary and recycled aggregates (including inert recycling), however it is possible that additional sites may be required during the plan period. Determination of proposals for such development will be made in line with Policy 8. Proposals for the development of secondary and recycled aggregate facilities should comply with the spatial strategy for waste management set out in the Local Plan (Policy 11). This type of facility typically produces noise and dust, therefore are most suitably located at industrial or existing waste sites, or disused railheads and wharves. At locations that are only temporarily in use, only temporary facilities will be permitted.

Policy 8 – Development criteria for secondary and recycled aggregate processing facilities

Proposals for the development of facilities for the handling, storage and processing of secondary and recycled aggregate materials (including inert recycling and inert CD&E wastes) should not conflict with the spatial strategy for waste management. Preference will be given to locations within:

- existing industrial areas, or on land that is permitted or allocated for general industrial development,

- committed or allocated waste management / disposal facilities (including temporary facilities) where this accords with the type of waste management / disposal use at that location, and

- existing and disused railheads and wharves.

Development of temporary aggregate recycling facilities will be permitted at mineral extraction sites with existing processing plants, particularly where this allows for secondary and recycled materials to be processed or blended to achieve a higher quality end-use.

Development of temporary facilities for the recovery and recycling of inert materials, including inert CD&E wastes, must demonstrate that the materials will be recycled and re-used (as far as practicable) onsite.

Allocations for secondary and recycled aggregate facilities

No sites for the processing of secondary and recycled aggregates have been allocated in this Local Plan. Committed (permanent and temporary) sites, along with sites linked to key construction work, will provide a reasonable mix of secondary and recycled materials processing facilities. Other sites will come forward through the planning application process as appropriate, and be determined in line with Local Plan policies.

Plan 4: The spatial strategy for mineral extraction showing allocated sites for minerals development

Refractory minerals and clay

Refractory minerals and clay are used for a variety of industrial purposes. Within Northamptonshire these materials are primarily used for engineering works and fill including the lining and capping of landfill sites. A number of limestone and landfill sites have permission to extract refractory minerals and clay (on site) for such purposes.

The quantity of refractory minerals and clay used for such purposes is not significant. Demand within the county can therefore be met through such incidental working, or through the use of alternative materials. No sites for the extraction of refractory minerals and clay have been allocated in the Local Plan. Proposals for such extraction will need to be made having specific regard to Policy 3.

Borrow pit extraction

There is often a need for large quantities of aggregates or clay for major construction and engineering works (such as road improvements). In some instances, it will be preferable to supply mineral from a borrow pit in close proximity to the construction works rather than creating additional heavy traffic by importing material from elsewhere. Determination of proposals for such development will be made in line with Policy 9.

Sites will need to be either progressively restored or restored as quickly as possible upon cessation of the project. Restoration of the borrow pit should utilise inert waste arising or extracted from the construction project in question.

Policy 9 – Development criteria for borrow pit extraction

Proposals for the development of borrow pits for mineral extraction must demonstrate that the:

- borrow pit is in close proximity to the construction project it is intended to supply,

- use of the mineral would not constitute an inappropriate use of high quality materials,

- mineral can be transported with minimal use of the public highway,

- site will be satisfactorily restored either through progressive restoration or as soon as possible following cessation of the construction project it serves, and

- inert waste arising or extracted from the construction project is utilised in restoration works (of the borrow pit).